What Is a Wire Crimper and Why Every Electrician Needs One

In the world of electrical work, one tool that no professional or DIY enthusiast can afford to ignore is the wire crimper. Whether you’re setting up solar panels, working on an industrial system, or fixing household wiring, a wire crimper is essential for ensuring safe, strong, and lasting electrical connections.

In this blog, we’ll explore everything you need to know about wire crimpers, including the different types like the hydraulic crimping tool, MC4 crimping tool, and lug crimping tool, and why every electrician needs at least one of these in their toolbox.

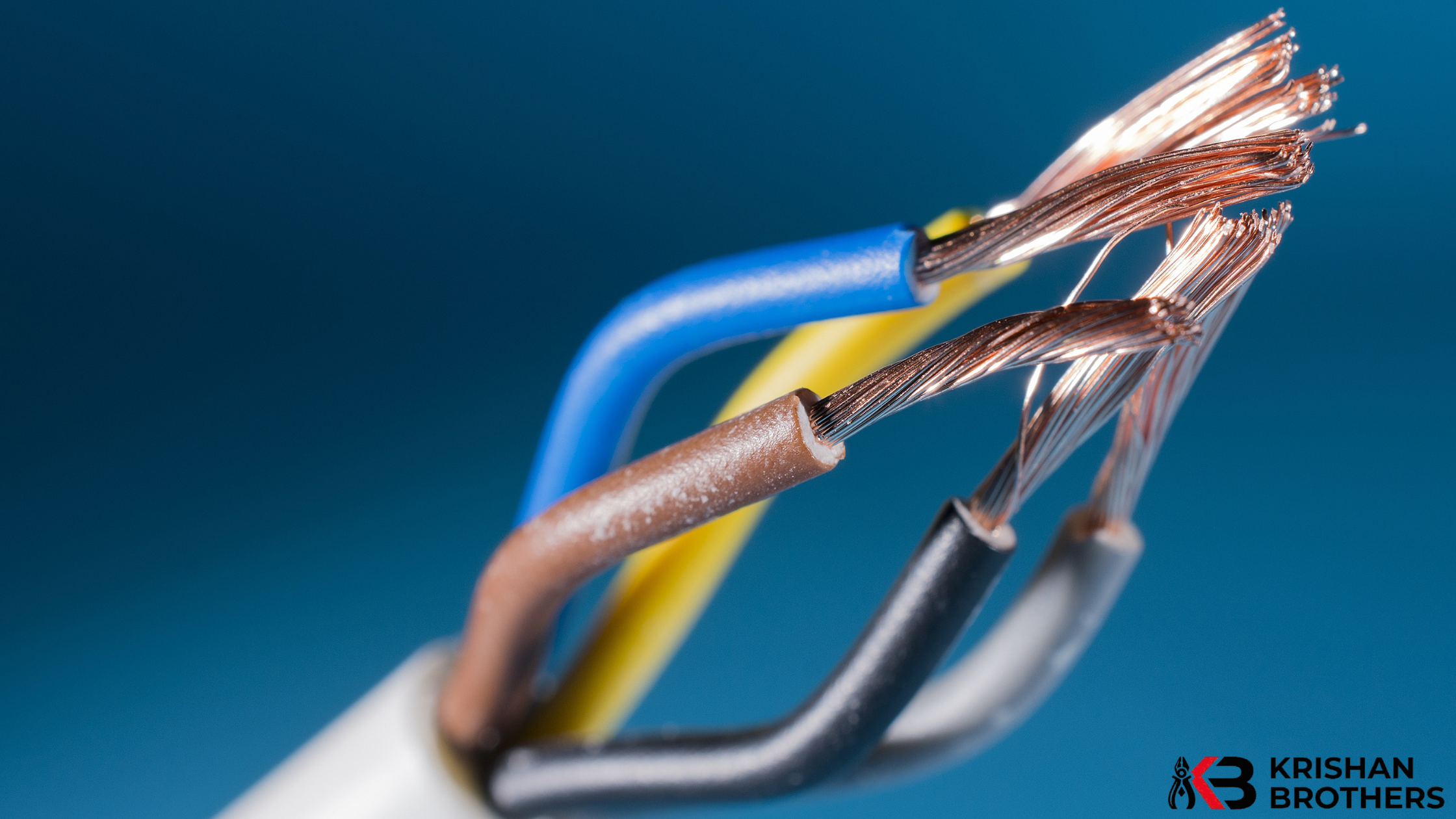

What Is a Wire Crimper?

A wire crimper is a hand tool used to join two pieces of metal by deforming one or both of them to hold each other. The crimping process is widely used in electrical work to attach connectors to the ends of wires without the need for soldering.

Instead of using heat, a wire crimper compresses the connector onto the wire, creating a secure, conductive, and durable connection. This is critical for both safety and functionality in electrical systems.

Why Is a Wire Crimper So Important?

Here are a few reasons why a wire crimper is a must-have:

1. Strong Electrical Connections

Crimping creates a firm bond between the wire and terminal, which ensures efficient electricity flow without interruptions or overheating.

2. Saves Time

Unlike soldering, crimping doesn’t require waiting for heat-up or cooling. This speeds up installation and repair processes.

3. Safety

Properly crimped connections reduce the risk of short circuits, sparks, and electrical fires.

4. Professional Finish

A crimped wire connection looks neat and tidy—important for both safety inspections and professional jobs.

Types of Wire Crimping Tools

Wire crimpers come in various types, each designed for specific uses. Let’s explore the most common and important ones.

1. Basic Wire Crimping Tool

The wire crimping tool is the most commonly used crimper. It’s a handheld tool that allows electricians to manually crimp terminals onto wires. These tools come in different shapes and sizes, depending on the type and thickness of the wire and terminal.

Features:

Manual operation

Suitable for low- to medium voltage tasks

Affordable and easy to use

Best For:

Household electrical jobs

Auto wiring

General purpose wiring

2. Hydraulic Crimping Tool

The hydraulic crimping tool is used for heavy-duty electrical work. It uses hydraulic pressure to generate a strong crimp, which is essential for thick cables and industrial applications.

Features:

High-pressure crimping

Can crimp large cable lugs

Ideal for copper and aluminum cables

Best For:

Industrial installations

Power distribution panels

Thick wire and lug crimping

Why Electricians Love It

This tool reduces physical effort and ensures a consistent crimp every time. It’s especially useful when working with high-capacity wires or in tight spaces where manual force is hard to apply.

3. MC4 Crimping Tool

The MC4 crimping tool is specifically designed for solar panel installations. It is used to crimp MC4 connectors, which are the standard in solar PV (photovoltaic) systems.

Features:

Compatible with MC4 connectors

Precise and clean crimp

Ensures a weatherproof connection

Best For:

Solar panel installations

Renewable energy projects

Outdoor electrical setups

Keyword Variation:

Sometimes called an MC4 crimper, this tool ensures you can confidently wire your solar panels knowing the connection will hold up in harsh outdoor environments.

4. Lug Crimping Tool

The lug crimping tool is used to attach lugs—metal connectors that are bolted or screwed into place—to the ends of thick wires or cables.

Features:

Designed for large gauge wires

Can handle various lug sizes

Some are hydraulic for extra power

Best For:

Electrical panels

Battery systems

Industrial cable termination

Using a lug crimping tool ensures that large wires are safely connected to terminals without the risk of fraying or coming loose.

How to Use a Wire Crimper (Step-by-Step)

No matter the type of crimper you are using, the basic steps are similar:

Step 1: Strip the Wire

Use a wire stripper to remove about 1/4 inch of insulation from the end of the wire.

Step 2: Insert the Terminal

Slide the bare wire into the terminal or connector until it’s snug.

Step 3: Choose the Right Crimping Slot

Wire crimpers have different slots for different terminal sizes. Select the correct one based on your connector.

Step 4: Crimp

Squeeze the crimper handles together with steady pressure. For hydraulic crimping tools, pump the handle until the crimp is complete.

Step 5: Inspect

Ensure the wire is tightly held by the terminal and that no copper strands are sticking out.

Tips for Buying the Right Crimping Tool

Check Compatibility:

Make sure the crimper matches the wire gauges and connector types you use.

Comfort Matters:

Look for ergonomic handles, especially if you do a lot of crimping daily.

Quality Over Price:

Don’t compromise on build quality. A good crimper lasts longer and gives better results.

Multifunction Features:

Some tools combine crimping, cutting, and stripping functions in one. Great for saving space!

Wire Crimper vs. Hydraulic Crimping Tool

Here’s a quick comparison to help you choose:

Feature Wire Crimper Hydraulic Crimping Tool

Force Type Manual Hydraulic

Best for light- to medium-duty jobs Heavy-duty and industrial

Cost Affordable Higher investment

Portability Very portable Bulkier, less portable

User Effort High/Low

If you’re working with small wires, a manual wire crimping tool is sufficient. But for big projects or thick cables, you’ll want the extra power of a hydraulic crimping tool.

Why Every Electrician Needs a Wire Crimper

It’s a Basic Necessity:

From small home repairs to large commercial jobs, crimping is everywhere.

Regulatory Compliance:

Electrical codes often require crimped connections for safety and reliability.

Versatility:

Tools like the MC4 crimper and lug crimping tool expand your ability to work on specialized systems like solar panels or high-capacity wiring.

Saves Time and Money:

Crimped connections are faster and cheaper than soldering, especially in fieldwork.

Prevents Future Problems:

A poor connection today can cause big headaches tomorrow. Crimping tools help you do the job right the first time.

Conclusion

The wire crimper might seem like a simple tool, but it plays a crucial role in ensuring the safety, efficiency, and reliability of every electrical connection. Whether you’re an apprentice electrician or a seasoned pro, investing in the right crimping tools—like a hydraulic crimping tool, MC4 crimping tool, or lug crimping tool—can take your work to the next level.

With various options available for different applications, understanding the tool’s function and selecting the right one for your needs is key. Crimping isn’t just a technique—it’s a skill every modern electrician must master.